Watch CrossWind in Action!

You design it, We'll machine it!

Who is CrossWind Machining &what we can do for you!

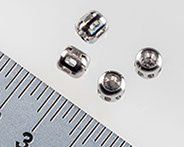

Using the latest computer-controlled state-of-the-art equipment, CrossWind Machining

is a Swiss Screw Machine Shop that specializes in providing high quality, machined metal & plastic components to device manufacturers & assembly companies. Today, multiple industries need CNC Swiss Screw Machining technology to meet the precision demands of a myriad of contemporary technological needs including Medical Device, Aerospace, microwave and Electronics. With 6-7 axis high speed machining capability, our machines can hold tolerances of +/- .0001 and can perform both turning and milling in a single operation. Thus, easily accomplishing our customers’ demands for extreme, high precision and quality finishes at high speed production capacity and often reducing or even eliminating the need for second operation processes. Partnering with CrossWind Machining

and our highly experienced team can make your design(s) more “manufacturable” while still maintaining the highest quality and in many cases, improving your bottom line cost!

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Welcome to CrossWind Machining!

ABOUT US

Our Quality Policy

CrossWind Machining believes that the customer’s best interests are what drive our business. We want to help you reach your goals. We take pride in our products and in the CrossWind reputation. Our #1 priority is to consistently meet or exceed our customers’ expectations in both quality and service.

CrossWind Machining, Inc. is ISO 13485:2016 Certified and committed to providing our customers the highest level of quality products and service.

We strive to serve our customers with honesty and integrity as we believe this effort will create a stronger, more enduring and beneficial connection between the parties. Our goal is to not only win the customer’s business, but to continually retain it by the mutual trust relationship we have developed.

Our quality goals include the following:

- Top management is committed to our Quality Management System and continually works to comply with and maintain the requirements and effectiveness of the system.

- Quality objectives are established and reviewed no less than annually.

- Top management ensures that this policy is communicated and understood throughout the organization.

At CrossWind, we train our machinists to understand more than just the basics of machining. We pride ourselves with our ability to combine the latest CNC technology with over 40+ years of machining skill and experience.

(For machine & material capabilities, treatment & finish capabilities and industries we service, please see the "Capabilities" tab/menu) at the top of the page.

CAPABILITIES:

MACHINES & TOOLING LIST:

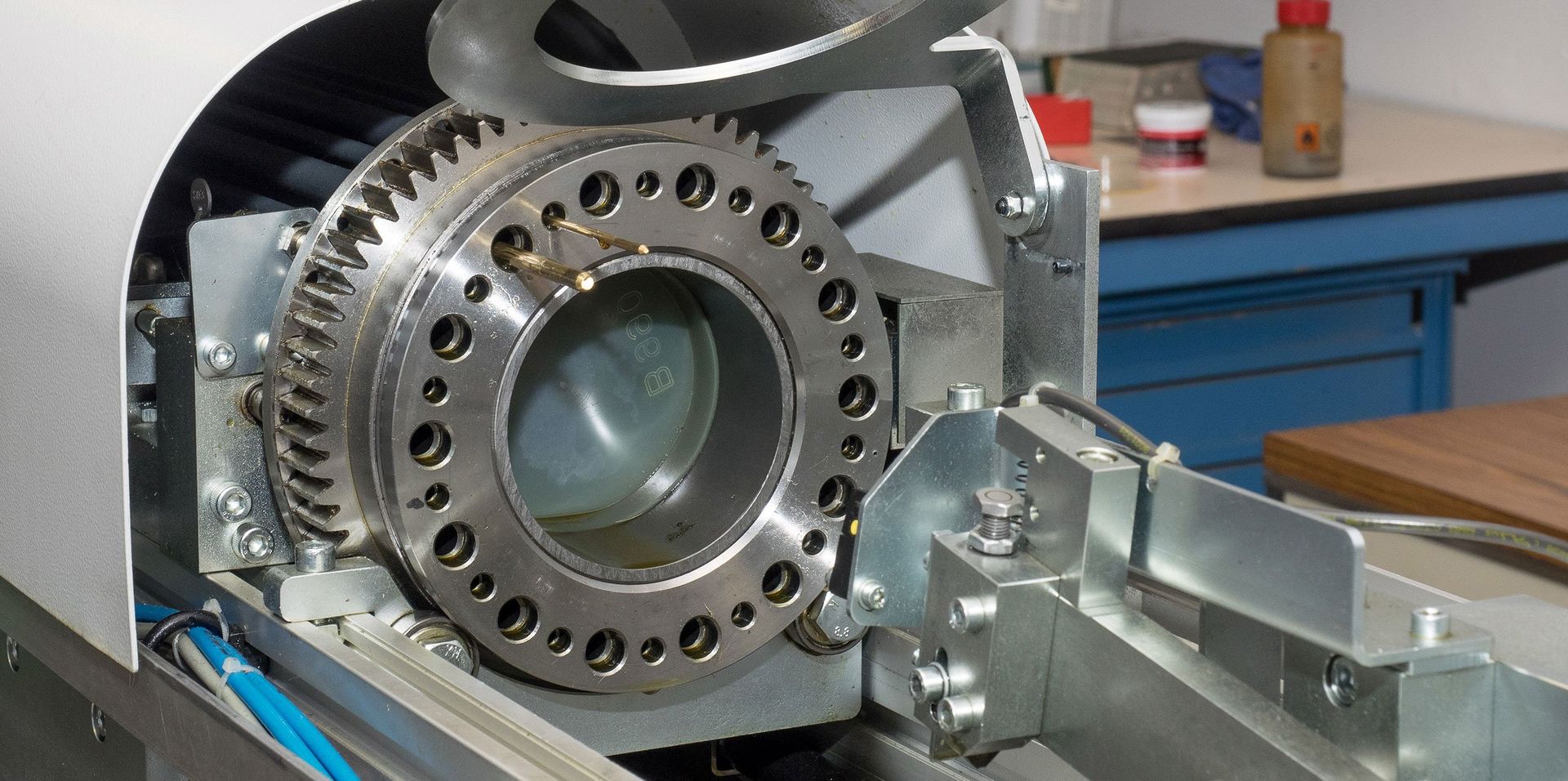

Check out our list of computer controlled and state-of-the-art equipment with sub-micron resolution.

- (2000) Star SE-12 CNC Swiss 6 Axis Screw Machine

- (2001) Star SR-20R CNC 6 Axis Swiss Screw Machine w/sub-spindle

- (2003) Star SR-20R Type II CNC 7 Axis Swiss Screw Machine w/sub-spindle

- (2006) Star SR-10J CNC 6 Axis Swiss Screw Machine w/sub-spindle & Tryton Bar Loader

- (2010) Star SR-20R Type III CNC 7 Axis Swiss Screw Machine w/sub-spindle & high pressure coolant

- (2013) Star SR-32J CNC 7 Axis Swiss Screw Machine w/sub-spindle, high pressure coolant & Express 332 Bar Loader

- (2015) Star SR-20JC CNC 7 Axis Swiss Screw Machine w/sub-spindle, high pressure coolant & LNS Alpha ST320 Bar Loader

- (2017) SB-20RG CNC 7 Axis Swiss Screw Machine w/sub-spindle, high pressure coolant & LNS GT-326 E-LP Bar Loader

- Live Tooling on Screw Machines

- Hydro-dynamic Bar Feeds on CNC Turning Machines

- Bridgeport Vertical Manual Mill

- 2 Hardinge manual lathes (for Second-Ops)

- Vaniman Microblaster for texturing and/or deburring

- 8 Stereo Microscopes + 2 Toolmakers Microscopes

- Keyence 8010 Optical Comparator

CrossWind Machining

12091 N. Tracey Ave.

Hayden, ID 83835

Ph: (208)315-6860

Fax: (208)315-6862

©

Copyright

2008 -

CrossWind Machining, Inc.

©

Copyright

2008 -